Industrial Automation System

Robot Control System

AWS (Automatic Welding System)

It is a robot control system for auto welding applied to the construction of oil carrying pipe lines, and it is adopted and operated in many construction sites in the world since it reduces work fatigability in manpower and makes working period shorter, and improves welding quality.

AGV (Autonomous Guided Vehicle System)

It is a key control system to harbor automation to improve distribution system according to the increase of harbor traffic, and it has various functions such as location recognition of autonomous guided vehicle, optimal path planning, running, collision avoidance, and it can be applied in many industries.

ROV (Remote Operating Valve System)

It is a system to operate balancing valves installed at the bottom of a ship in the deck remotely and it provides efficient and economic effects in construction and maintenance since it consists of LonWorks PLC communication.

It is a robot control system for auto welding applied to the construction of oil carrying pipe lines, and it is adopted and operated in many construction sites in the world since it reduces work fatigability in manpower and makes working period shorter, and improves welding quality.

AGV (Autonomous Guided Vehicle System)

It is a key control system to harbor automation to improve distribution system according to the increase of harbor traffic, and it has various functions such as location recognition of autonomous guided vehicle, optimal path planning, running, collision avoidance, and it can be applied in many industries.

ROV (Remote Operating Valve System)

It is a system to operate balancing valves installed at the bottom of a ship in the deck remotely and it provides efficient and economic effects in construction and maintenance since it consists of LonWorks PLC communication.

Safety System

Crane Collision Avoidance System

Crane collision avoidance system is to prevent crane collision accident between the cranes which can occur in shipbuilding and construction industries. The system consists of precision DGPS, wire-wireless network integrated control system and console devices for users.

u-Safety

Disaster prevention management system is to prevent industrial disasters in advance by collecting and analyzing the factors causing disasters such as fire, explosion, suffocation and fall which can occur in general industries of shipbuilding, chemistry, construction and other industries through wirewireless sensor network and integrated control system.

Crane collision avoidance system is to prevent crane collision accident between the cranes which can occur in shipbuilding and construction industries. The system consists of precision DGPS, wire-wireless network integrated control system and console devices for users.

u-Safety

Disaster prevention management system is to prevent industrial disasters in advance by collecting and analyzing the factors causing disasters such as fire, explosion, suffocation and fall which can occur in general industries of shipbuilding, chemistry, construction and other industries through wirewireless sensor network and integrated control system.

Offshore Pipeline

Auto-welding System

Auto-welding System

This is the track driving all-posture auto-welding system used for welding onshore and offshore pipes. It consists of the controller, welder and robot that performs welding in 5G postures under difficulty of rotation or movement of the pipe spool.

Users save various welding conditions in database in the controller depending on the pipe size and its material, the wire size and its material and welding posture. The controller that is set with these conditions, welds the pipes and sends commands to the welder and welding robot so that a proper welding condition can be applied to the situation the welder meets.

- Welding Technique : FCAW or GMAW

- Welding Type : Root, Hot pass + Fill, Cap pass

- Automatic change in welding condition based on welding postures(5G)

- Single carriage with dual torches

- Simultaneous welding with two carriages divided into port and starboard

- Auto voltage(current) control : Torch height auto tracking

- Seam tracking : Torch center auto tracking

- Light guide ring able to cope with various pipe sizes

- Modularized carriage structure : easy maintenance

Overview

Features

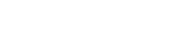

Diagram

Onshore Pipeline

Auto-welding System

Auto-welding System

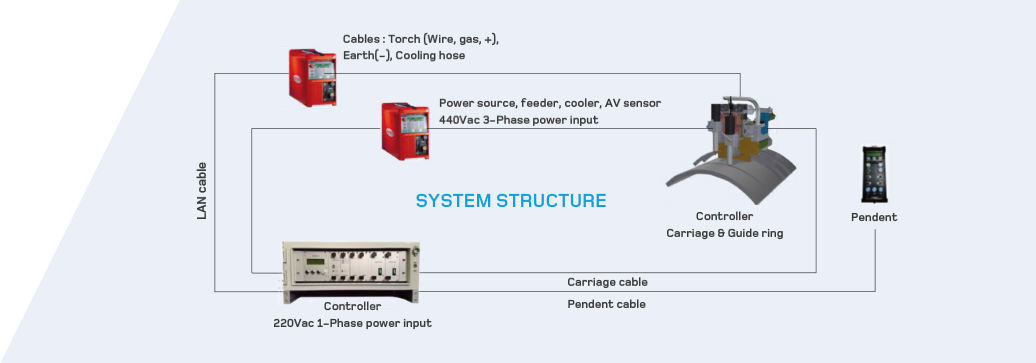

This is the track driving all-posture auto-welding system used for welding onshore and offshore pipes. It consists of the controller, welder and robot that performs welding in 5G postures under difficulty of rotation or movement of the pipe spool.

Users save various welding conditions in database in the controller depending on the pipe size and its material, the wire size and its material and welding posture. The controller that is set with these conditions, welds the pipes and sends commands to the welder and welding robot so that a proper welding condition can be applied to the situation the welder meets.

- Application to oil pipe, gas pipe, onshore/offshore plant

- Able to apply to various welders :

Lincoln (CAN, DeviceNet), Miller (485, Modbus), Fronius (LAN, Modbus UDP) - Use of various guide rings such as fixed type or self-assembly type

- Torch motion control with high degree of freedom :

Enables Driving, Weaving, Height and Tilt - Extension of supplying wire (option, push-pull manner)

- Enables failure diagnosis, remote welding control and monitoring

- Able to apply for bigger that 12 inches and horizontal welding

Overview

Features

Diagram

All-position Light Fillet

Carriage

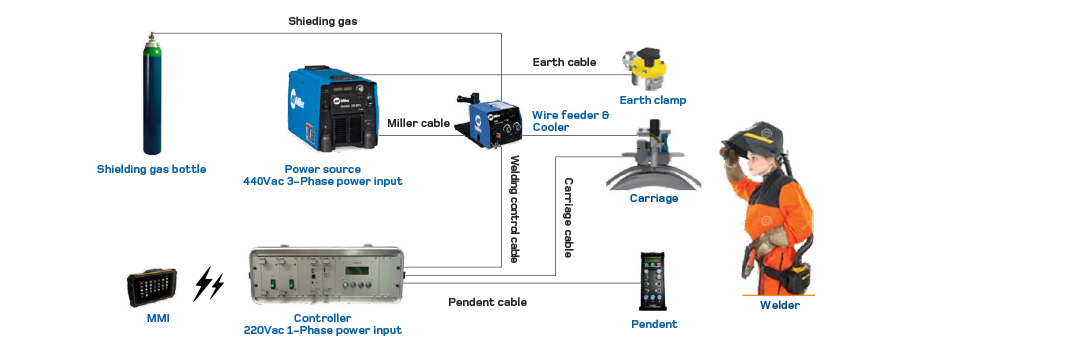

Carriage

This automatic welding carriage is used for butt welding, vertical welding, horizontal welding, flat position welding, etc. It has a function of left/right stop to prevent short welding on weaving welding. The driving speed can be seen on driving through the driving speed window. Manual transfer is possible on a rail due to the neutral clutch function. The rail is small-sized and light, providing easy transfer. It also gives easy attachment/detachment using the magnet attachable/detachable manner.

- Light design : 5.7kg

- Constant speed control algorithm : Speed setting screen available

- Various weaving functions : width, speed, L/R stop time setting

- Function of torch center movement : able to move during welding

- Able to set continuous/sporadic welding mode

- Provides welder control interface(voltage, current, inching, gas check)

- Applied small/light rail of detachable magnetic type

- Able to change the design of torch driving part according to welding method

Overview

Features

Diagram

Utility

Features 1

Features 2

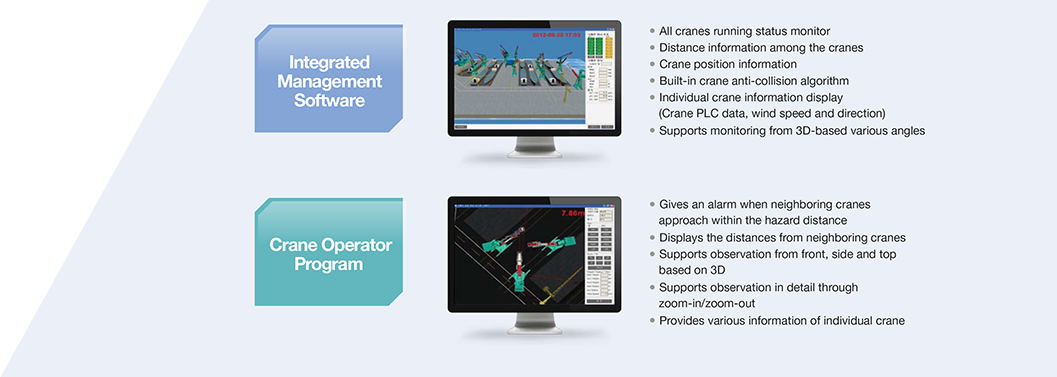

Crane Anti-collision

System

System

This system prevents multiple cranes running in a dock from colliding each other. GPS receivers are installed on the cranes respectively. They receive and transmit GPS coordinates to server through a wireless network.

The server that receives the GPS data, figures out the distances among the cranes, predicts possible danger of collision among the cranes and transmit the information to each crane so that the operators can run the cranes carefully. When the cranes get close within the distance set in the system, the cranes in question stop automatically through the management software.

- Crane position recognition and automatic control system

- Automatic stop control interconnected to the crane PLC

- User interface device - Stable communication network

- Wireless mesh network communication - Real time detection of cranes in operation

- High precision RTK DGPS, tilt angle sensor - Wire/wireless network technology to transmit collision/sensor information

- Builds high performance mesh network, RF network

- Wire communication of the sensor information(GPS, tilt angle, etc) within the crane

- Applied standard communication control technology – Industrial Field BUS LonWorks

(ANSI EIA 709.1) - Linear algorithm/Anti-collision control algorithm

- Detail information coming from 3D Modeling and linear algorithm

- Interoperable to GIS-based industrial site information

Overview

Features

Diagram

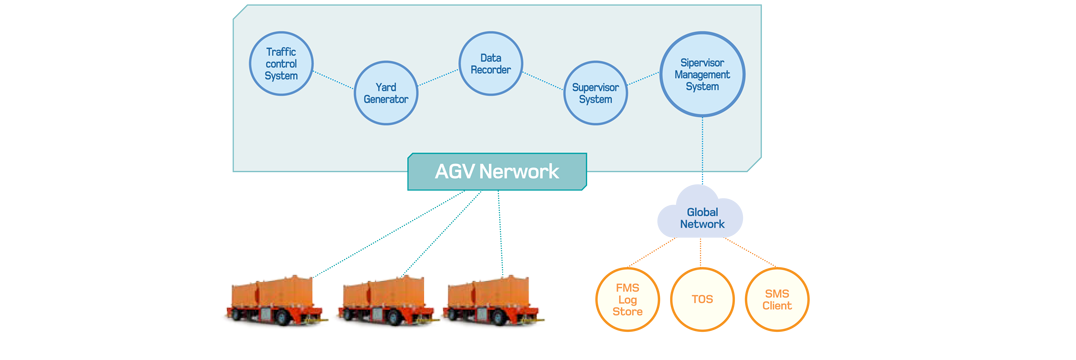

AGV

Autonomous Guided Vehicle

Autonomous Guided Vehicle

AGV(Autonomous Guided Vehicle) is unmanned autonomous driving transport equipment.

This AGV has applied cutting edge automatic control technology and efficient software that improve efficiency, operability, economic feasibility, to existing product transport that has run on humans.

- Automation of port/airport logistics system

- Automation of warehouse and cargo terminal

- Automation of industrial product transport and shipping system

- Automation of product flow in production facility

- R&D in logistics automation project

Overview

Features

Download

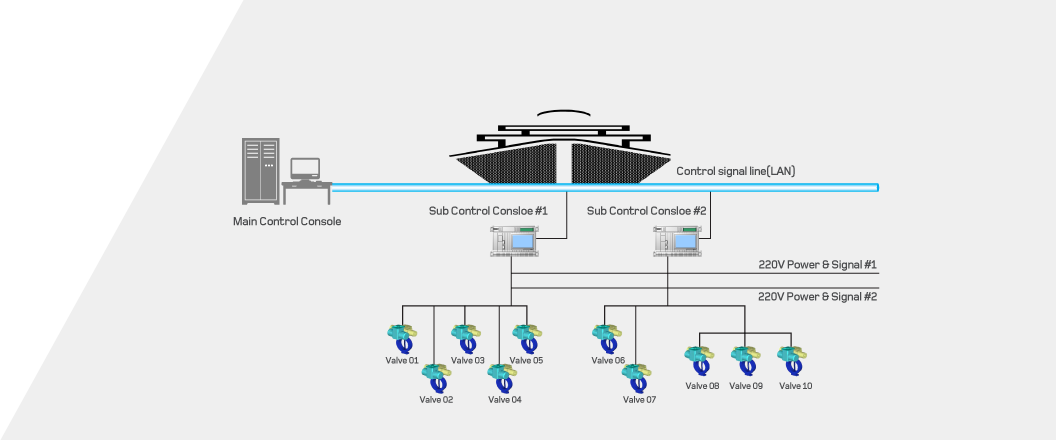

Remote Operating Valve

System

System

This system is to control opening/closing of large-sized water pipe or oil pipe remotely from tens of mm to thousands of mm in diameter.

The existing remote control valve requires excessive pipe and electric wiring jobs, but this new system uses the valve actuator that integrates the small-sized hydraulic power pack, and adopts power line communication, clearing the existing problems, reducing installation period and enhancing efficiency.

- System control using power line communication of next generation's

technology (ANSI/EIA 709.1) - Built-in small-sized hydraulic power pack to remove hydraulic pipe

- Equipped with cutting edge valve control system with artificial intelligence

Overview

Features

Diagram